Reindustrialization: Why Mastering Third Parties Is Now a Strategic Imperative

France’s reindustrialization is underway. Driven by the ambitions of the France 2030 plan, the ecological transition, and economic sovereignty challenges, it’s about much more than simply bringing factories back onto national soil. It requires a deep rethink of sourcing, evaluation, and supplier management processes.

Restoring independence and economic sovereignty has become a major strategic issue for Europe. The pandemic, geopolitical tensions, and supply chain crises have revealed our dependency on fragile, globalized value chains. Reindustrialization reflects the will to regain control over production capabilities, secure essential supplies, and create sustainable jobs across our regions.

Yet the current context doesn’t favor this shift. Energy costs remain prohibitive, particularly for manufacturers facing Chinese competition, whose overproduction capacity weighs heavily on global markets. Add to that signs of instability — tariff threats in the U.S., fiscal uncertainty in France — which dampen the long-term investments needed to bring strategic activities back home.

Still, reindustrialization represents more than just an economic issue. It’s a lever for innovation: by bringing production centers closer, buyers and suppliers can collaborate more efficiently, accelerate innovation cycles, and improve agility. The renewed industrial fabric becomes a living ecosystem, more responsive, more resilient, and more virtuous.

Reindustrialization is also a civic act. It responds to consumer expectations for more local, sustainable, and ethical products. It supports local employment, promotes know-how, and contributes to the green transition. In short, reindustrializing is about building a more sovereign and citizen-focused economy.

France 2030 Must Be Anticipated by Procurement Leaders

The €45 billion France 2030 plan aims to actively support national reindustrialization, while accelerating the decarbonization of industry and fostering next-generation technologies. This dual ambition is clear: bring back production sites to French territory and align them with ecological transition and technological innovation.

Reindustrialization Demands a New Approach to Supplier Panels

Historically driven by cost reduction, Procurement Departments are now rethinking their paradigms. Relocation, supply chain diversification, and developing local networks are now strategic imperatives — but they also bring new complexity.

In this context, optimized supplier management is a key success factor. It’s no longer just about evaluating a supplier’s price or lead time — it’s about assessing resilience, compliance, ESG performance, and their ability to support secure and sustainable production.

Reindustrialization: What’s Changing for Businesses?

Buyers are turning to closer, often locally-based partners, who are already engaged in legal compliance, cybersecurity, and environmental performance initiatives. One of the key challenges is to assess the maturity of these efforts to identify the most reliable and aligned suppliers.

In sensitive sectors such as healthcare, energy, or technology, the need for compliance is even greater. Regulatory pressure is intensifying, and traceability is now essential at every stage of the value chain. Buyers must demonstrate their ability to manage risks related to every third party — from data security and ethical practices to environmental impact.

Even as companies refocus their supplier panels around local actors, some dependencies remain — critical materials, components, or semi-finished products are still produced in distant or unstable regions. In this case, increased vigilance is needed, especially regarding the Duty of Vigilance law and other international frameworks. The goal: apply a consistent risk management policy across the entire supply chain, regardless of supplier profile or location.

This shift also results in a proliferation of local suppliers, all requiring systematic and rigorous evaluation. It’s no longer just about price and delivery: companies must assess quality, cybersecurity, resilience, and social/environmental compliance. Supplier management is now at the heart of tomorrow’s industrial strategy.

TPRM: A Key Enabler for Industrial Transformation

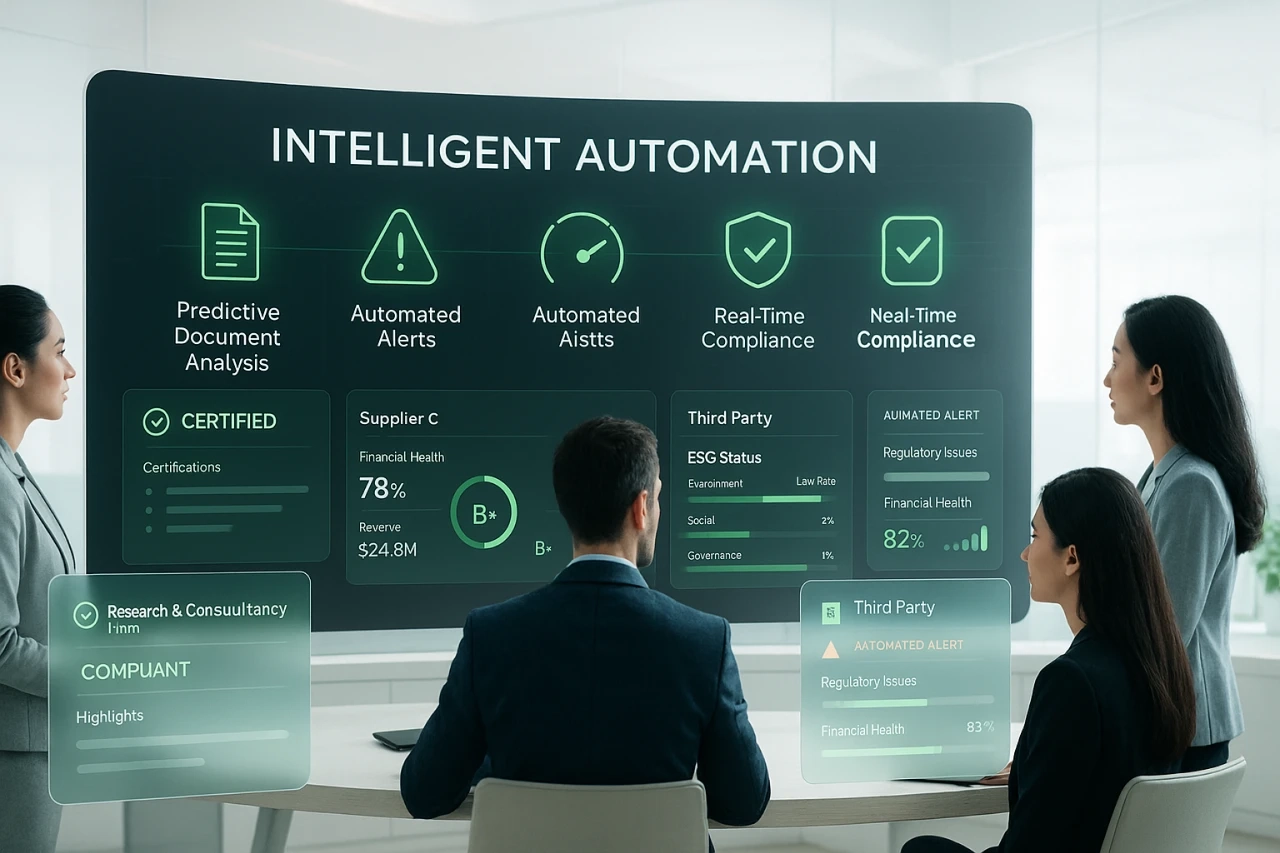

In this landscape, Third-Party Risk Management (TPRM) tools are emerging as essential allies. Why?

To support industrial strategies, organizations need to map, segment, and qualify suppliers according to relevant criteria aligned with relocation and production priorities. This approach allows them to monitor third-party risks — reputational, regulatory, or operational — throughout the entire supplier relationship.

By identifying early warning signs, companies gain in resilience and responsiveness. And when TPRM tools are integrated into your core systems (ERP, SRM, PLM), you achieve connected, streamlined, and sustainable supplier governance.

Reindustrialization enables better third-party evaluation, beginning at the sourcing stage — giving buyers greater leverage to demand more from their supplier panels.

The Tangible Benefits of TPRM in a Reindustrialization Project

Implementing a TPRM solution within a reindustrialization strategy helps to:

Secure nearshoring efforts by ensuring more reliable supplier data and regulatory compliance

Accelerate onboarding of local partners through structured evaluations

Align ESG and industrial goals by integrating ESG criteria into selection workflows

Industrialize supplier assessments and monitoring, while ensuring transparency in decision-making

Support responsible procurement and sovereignty goals with shared, auditable, and actionable tools

Real-World Example: Relocating with Confidence

Let’s take the case of a French industrial group that relocated part of its production. To identify and evaluate local suppliers quickly — while ensuring compliance — they deployed a TPRM solution integrated with their ERP.

The result: a significant time saving during the sourcing phase, better risk control with new suppliers, and stronger governance over ESG commitments.

Drive reindustrialization with confidence

Mastering your third parties is a strategic lever to relocate with peace of mind. Discover how Aprovall360 helps you structure your assessments, secure your partners, and accelerate your industrial projects.

These articles might interest you

-

16 July 2025TPRM & Innovation: How Procurement Departments Are Becoming Catalysts for Product PerformanceSecteurInnovation is no longer a luxury. For industries such as manufacturing, construction, luxury goods, or retail, it is a strategic necessity — essential for differentiation, regulatory compliance, and staying competitive in increasingly volatile markets. As products become more complex and development cycles accelerate, Procurement Departments are being called to the forefront. Their mission goes far […]

16 July 2025TPRM & Innovation: How Procurement Departments Are Becoming Catalysts for Product PerformanceSecteurInnovation is no longer a luxury. For industries such as manufacturing, construction, luxury goods, or retail, it is a strategic necessity — essential for differentiation, regulatory compliance, and staying competitive in increasingly volatile markets. As products become more complex and development cycles accelerate, Procurement Departments are being called to the forefront. Their mission goes far […]Read more

-

02 June 2025The 6 Pillars of an Effective Supplier Evaluation SolutionSecteurAccording to a 2025 Accenture study, 63% of companies are undergoing transformation. As a result, CIOs, procurement managers, and compliance officers are rethinking their approach to third-party governance. In both public and industrial sectors, it is no longer just about collecting administrative documents, but about structuring supplier relationship management to sustainably strengthen operational resilience. Adopting a collaborative evaluation solution based […]

02 June 2025The 6 Pillars of an Effective Supplier Evaluation SolutionSecteurAccording to a 2025 Accenture study, 63% of companies are undergoing transformation. As a result, CIOs, procurement managers, and compliance officers are rethinking their approach to third-party governance. In both public and industrial sectors, it is no longer just about collecting administrative documents, but about structuring supplier relationship management to sustainably strengthen operational resilience. Adopting a collaborative evaluation solution based […]Read more

-

05 June 2025Automated Evaluation Solutions: How to Streamline Without Sacrificing QualitySecteurAutomating evaluations is becoming an essential step for organizations looking to strengthen their third-party governance. IT decision-makers, especially in construction, industry, and the public sector, are seeking to combine efficiency and time savings with uncompromising quality assurance. Given concerns around the reliability of automation tools and the need for consistent performance, it’s crucial to debunk myths with recent advances in AI and intelligent […]

05 June 2025Automated Evaluation Solutions: How to Streamline Without Sacrificing QualitySecteurAutomating evaluations is becoming an essential step for organizations looking to strengthen their third-party governance. IT decision-makers, especially in construction, industry, and the public sector, are seeking to combine efficiency and time savings with uncompromising quality assurance. Given concerns around the reliability of automation tools and the need for consistent performance, it’s crucial to debunk myths with recent advances in AI and intelligent […]Read more

-

09 June 2025Optimizing ESG Evaluation Tools: Enhance Your Supplier ProcessesSecteurFaced with increasing regulatory pressure and the rise of sustainable transformation, organizations must rethink their third-party governance. Integrating ESG criteria into third-party evaluation tools has become a critical lever to meet regulatory requirements and the growing expectations of stakeholders. Even with the temporary suspension of CS3D, many companies now view supplier ESG commitment as a key risk factor […]

09 June 2025Optimizing ESG Evaluation Tools: Enhance Your Supplier ProcessesSecteurFaced with increasing regulatory pressure and the rise of sustainable transformation, organizations must rethink their third-party governance. Integrating ESG criteria into third-party evaluation tools has become a critical lever to meet regulatory requirements and the growing expectations of stakeholders. Even with the temporary suspension of CS3D, many companies now view supplier ESG commitment as a key risk factor […]Read more